Rotary Airlock Valves

Rotary airlock valves are very popular in the Industry and are used to minimise system air loss while transferring materials between vessels with differential pressures or as volumetric feeders for metering materials at specified flow rates. Available in Cast iron, Cast Steel, Stainless Steel, Aluminum, Heat resistant Steel and other materials of construction from 100mm to 2000mm size to meet capacities upto 500M3/hr.

These airlocks are generally used to accomplish three basic tasks; to feed material from a bin or hopper, to deliver fines from a collector while sealing against air loss and feed material into a pneumatic conveying system against pressure.

Hyquip builds a heavier airlock to closer tolerances which means bettersealing properties. Ourairlocks are generally chosen for applications where air leakage and gas loss are of important considerations, even though they are also frequently specified for feeder applications because of their ability to withstand the abrasion and stress of heavy duty feeder applications.You can depend on Hyquip airlocks performing as specified, as our specifications are intentionally conservative to help ensure this.

Baggase Feeder

Bagasse being a typical material - light, fluffy, fibrous with very high moisture content demands for a special design than a standard Drop through airlock.

Bagasse being a typical material - light, fluffy, fibrous with very high moisture content demands for a special design than a standard Drop through airlock.

HYQUIP has perfected the construction of airlocks for this application and has many successful installations. The power demand for these airlocks are more than that of other applications.

Raw Mill Feeder

These airlock feeders are popularly used for feeding limestone lumps to raw mills and coal mill in cement industry to avoid false air entering in to the mill thereby decreasing its efficiency. It is so designed to pass hot steam through the rotor pockets to reduce moisture in the material, thereby avoiding clogging of material in the rotor pockets, resulting in the reduction of capacity. These Raw/Coal mill Feeders are easy to operate and are maintainable at much lower cost as compared to the Triple gate valves which are also employed for this application.

These airlock feeders are popularly used for feeding limestone lumps to raw mills and coal mill in cement industry to avoid false air entering in to the mill thereby decreasing its efficiency. It is so designed to pass hot steam through the rotor pockets to reduce moisture in the material, thereby avoiding clogging of material in the rotor pockets, resulting in the reduction of capacity. These Raw/Coal mill Feeders are easy to operate and are maintainable at much lower cost as compared to the Triple gate valves which are also employed for this application.Coal Feeder

These airlock feeders are popularly used for feeding limestone lumps to raw mills and coal mill in cement industry to avoid false air entering in to the mill thereby decreasing its efficiency. It is so designed to pass hot steam through the rotor pockets to reduce moisture in the material, thereby avoiding clogging of material in the rotor pockets, resulting in the reduction of capacity.

These Raw/Coal mill Feeders are easy to operate and are maintainable at much lower cost as compared to the Triple gate valves which are also employed for this application

These airlock feeders are popularly used for feeding limestone lumps to raw mills and coal mill in cement industry to avoid false air entering in to the mill thereby decreasing its efficiency. It is so designed to pass hot steam through the rotor pockets to reduce moisture in the material, thereby avoiding clogging of material in the rotor pockets, resulting in the reduction of capacity.

These Raw/Coal mill Feeders are easy to operate and are maintainable at much lower cost as compared to the Triple gate valves which are also employed for this application

Self Cleaning Rotary Airlock

The self cleaning airlocks are developed as a import substitute is used for feeding of lignite in power plants or any other sticky materials which tend to pack up in the rotor pockets.

The self cleaning airlocks are developed as a import substitute is used for feeding of lignite in power plants or any other sticky materials which tend to pack up in the rotor pockets.

It is so designed that the pockets are mechanically cleaned per revolution to avoid loss of rated capacity.

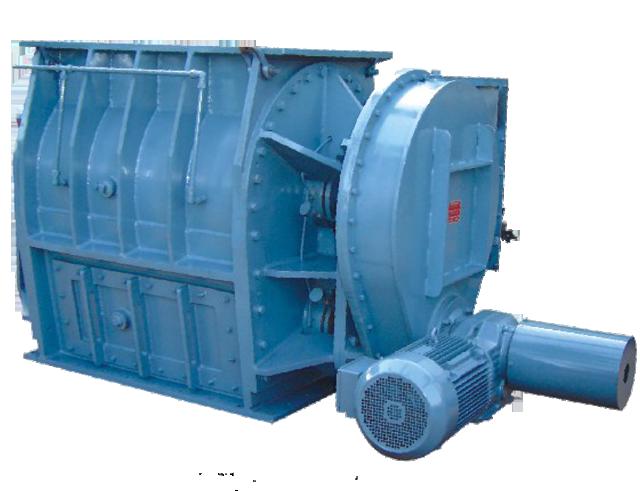

Steam Jackated Rotary Airlock

These airlocks are specially designed to feed lumpy materials like coal with high fines content which tend to pack due to moisture, there by jamming rotor. The housing is of a special design with side entry and jacketed to pass steam to remove moisture from the material being handled. The rotor is also of a very special design and constructed from highly abrasive resistant materials with spring loaded inlet to feed it.

These airlocks are specially designed to feed lumpy materials like coal with high fines content which tend to pack due to moisture, there by jamming rotor. The housing is of a special design with side entry and jacketed to pass steam to remove moisture from the material being handled. The rotor is also of a very special design and constructed from highly abrasive resistant materials with spring loaded inlet to feed it.